Westrock Products are Designed with your Equipment Systems Needs in Mind

The precise material that your equipment needs depends on the size of the machine and the use and conditions of the application to which it is going to be submitted. Therefore, the properties of the friction material will be different according to the function and cyclic applications of your machine. At Westrock, we understand your business and can help you identify the type of friction materials that your equipment needs.

Westrock technology uses the appropriate formula in the development of the friction material required for your working conditions, giving reliability and a high level of productivity to your operation, resulting in a reduction of cost with excellent quality. Our engineers understand the importance of material resistance, giving the friction material the proper qualities, with consideration to the oil and other components of the system.

An incorrect design, or inadequate material, can cause premature wear, noise, overheating, chatter, etc., which can result in many problems. With Westrock products, you will be buying quality, not more problems.

Westrock Proves the Quality of its Products Through Performance

Westrock has invested millions of dollars in designing, testing and developing formulas of every material used in the friction field for all applications in machines all over the world. It is this process that has carried us through the years and has made us one of the world leaders in friction material.

All of our Westrock products are certified with our rigorous quality control systems, assuring the technical specifications required by the OEM.

Westrock offers the guarantee of security and reliability of its products through years of real world results in applications all over the globe, providing millions of operational machine hours.

Manufactured to Perform

Manufactured to Perform

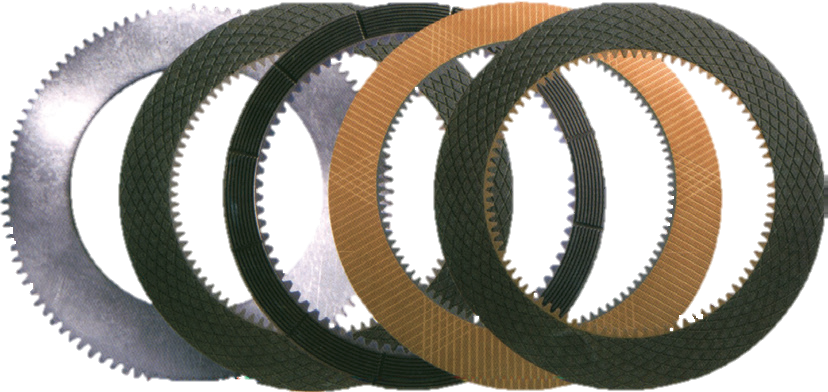

Friction material is the key to the success of the power train. Components manufactured with Westrock friction materials allow for the proper oil flow and heat dissipation, resulting in greater product life and lower maintenance costs than other brands. Therefore, it is important to select Westrock components when choosing spare parts for brakes, powershift transmissions or steering clutches.

Westrock friction materials have shown reliability and prolonged performance in many brands of machinery. Westrock provides guidelines of reusability so that you know what should be replaced - another way in which we help you take control of your costs and operation.

Built to Last, Even in Severe Conditions

Drive train components function under incredible stress. The capacity to perform under such conditions can signify important savings. Friction material used in Westrock components have been designed to last until normal overhaul and planned maintenance of the machine, or even longer. Its useful life can be coordinated with other components of the drive train allowing all repairs and changes to be performed at the same time - reducing repair costs and down time.

Westrock friction material is designed to meet the needs of power train components for machinery brands such as Caterpillar, Komatsu, John Deere, Clark, Allison and others.

Available in: Paper, Sintered Bronze, Elastomeric, Graphite, Steel